Joinery & Carpentry

This section is an introduction to joinery and carpentry and explains the difference between them.

They are both trades in the construction industry. Joinery is normally the 'joining of wood' in the workshop, whilst carpenters construct the elements on-site.

A day in the life of a joinery apprentice - click here

A day in the life of a carpentry apprentice - click here

A career in carpentry/joinery - click here

The resources we provide on this page are linked to our Mobile Construction Classroom teaching. The links to videos and existing websites are provided recognising their ownership and responsibility for the content.

Resources to Support Learning

Joinery & Carpentry in Construction

Within the construction industry there is a need for both joiners and carpenters for different elements of the project. For example in building a house:

A joiner has the skills to make the components needed such as floorboards, windows, doors, stairs and fitted furniture etc. They will normally work with wood only.

A carpenter has the skills to work on-site installing these wooden features in the house including floors, staircases, window frames and cupboards or shelving. This will involve the use of metal fixings, screws and nails to fit the component in place.

To work in either trade you need a good eye for detail, be able to work out measurements and to follow plans. Many of the practical skills of working with wood are used in both.

Tools

The tools used in both trades are largely the same:

Work Area

- Work Bench on which to work safely at a suitable height with the ability to hold materials tightly for working.

- Mitre Box is a tool used to guide a hand saw to cut timber at the correct angle for a joint .

Measurement

- Steel Ruler to measure lengths.

- Sliding Bevel to both set-out and measure angles.

- Tri Square to set out lines and check right angles.

- Marking Gauge is used to mark out lines for cutting.

- Tenon Saw has a very fine blade and is used in cutting dovetail joints.

- Chisel is often used with a mallet to cut across the grain of the wood and in cutting out a housing joint.

- Smoothing Plane is used ot smooth sawn timber prior to fitting it together.

Fixing

- Nail Punch is used to punch nails below the surface of the timber.

- Screwdriver is used to insert or remove screws.

- Claw Hammer is used to remove nails from wood.

Drilling

- Hand Drill is a drill which can be operated by hand or battery operated (hand held) and is used to drill holes in the timber to allow the securing of two elements together.

- Bradawl is used to start a hole in timber to more easily insert a screw.

Remember you will need to think about what PPE you will need for the work you are doing, find out more here

Materials

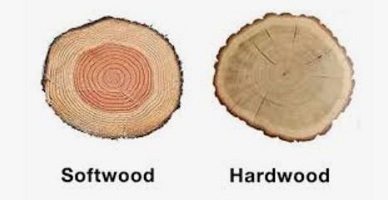

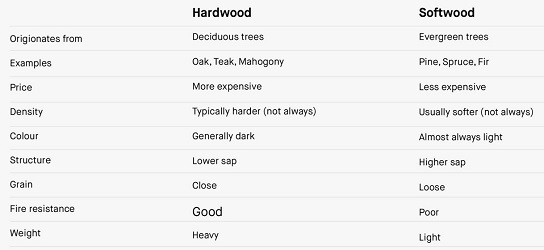

Timber is the main material used in both trades. There are 3 main types of timber:

- Softwood comes from a conifer tree which is usually evergreen

- Hardwood comes from a deciduous treee which looses its leaves each year

- Tropical hardwood comes from forests in tropical regions and is often claimed to be sustainable as it can be 'harvested' as if it were a crop and re-grown quickly.

It is softwood that is commonly used in house buiding in the UK. This video shows how timber is made from logs - click here

Adhesives are used to join pieces of timber together. PVA glue is nost commonly used and is applied to both surfaces before clamping them together to apply pressure so the adhesive has time to set.

Woodscrews come in different lengths and sizes and can be easily removed from timeber. They are used to fix elements together for example a hinge to a door.

Techniques

All work with wood will include the use of joints to connect two pieces of timber together to make a structure. The basic joints are:

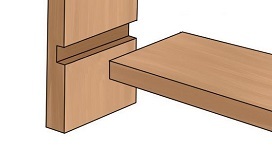

Housing Joint - where a slot is cut in one section of timber into which another fits to form a tight joint. They are normally glued together. It is used in bookshelves and making drawers.

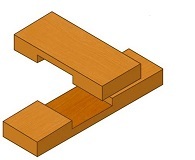

Tee Halving Joint - which forms a T shape by creating a channel in each piece of timber which is the width of the other. Each channel should be half the depth of the other piece to give a flush surface on both sides when fitted. They are normally glued together. It is often to strengthen a structure eg. in tables and chairs.

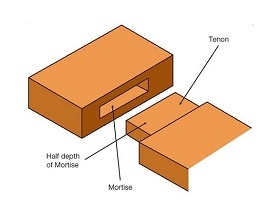

Mortice and Tenon Joint - the mortice part of the joint has a hole cut out which is the same size and length as the slot cut out of the other piece of timber. They fit together exactly and are normally glued together. It is traditionally used in joining frames and panels in doors and windows.

Watch these videos to learn more about how to make these joints:

Housing Joint - click here

Tee Halving Joint - click here

Mortice and tenon joint - click here

Contact Us